Paper Handle-Making Machine

Paper handle-making machine is mainly used for the production of twisted rope handles and flat rope handles, can also be used with semi-automatic paper bag machine for efficient production of handbags.

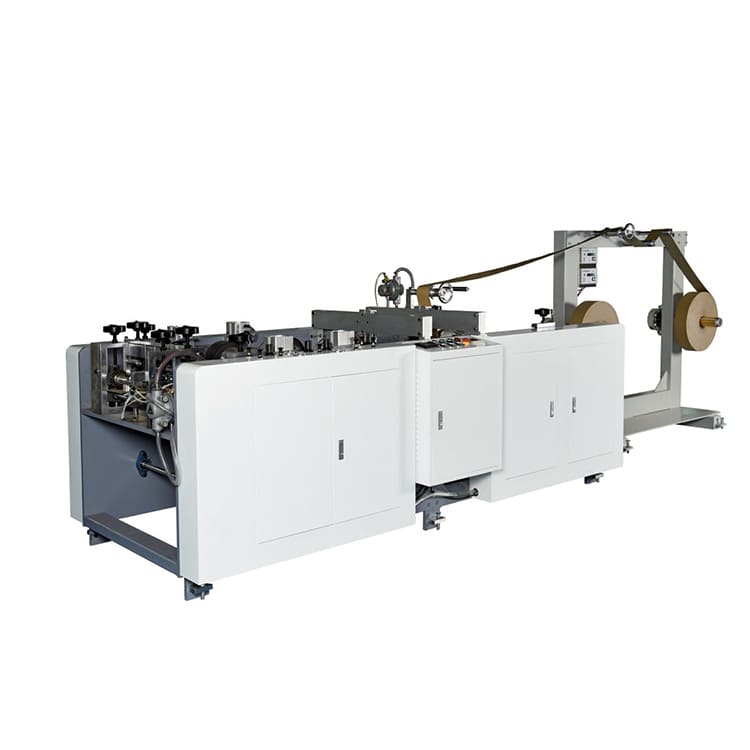

Twisted Paper Handle Making Machine

This machine is a high-speed machine for producing twisted paper handles. which can be attached to the paper bag without handles, and make it into paper handbags. This machine takes two narrow paper rolls and one paper rope as raw material, sticks them together for forming paper handles. In addition, the machine also has automatic counting and gluing functions, which can greatly improve the efficiency of subsequent processing operations of users.

It is an ideal supporting machine for paper handbag making machine.

Flat Paper Handle Making Machine

This machine is a high-speed machine for producing flat paper handles. which can be attached to the paper bag without handles, and make it into paper handbags. This machine takes four narrow paper rolls as raw material, through the complex production process to form right-angle flat paper handles. In addition, the machine also has automatic counting and gluing functions, which can greatly improve the efficiency of subsequent processing operations of users.

It is an ideal supporting machine for paper handbag making machine.

Table Of Contents For This Page

It is not easy to introduce all aspects of a twisted paper handle making machine, so we have prepared a lot of information on this page for your reference. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Applications For Twisted Paper Handle Making Machine

An ideal supporting machine for making a variety of different paper handbags. Its products can be used as shopping bags, food packaging bags, gift bags, transportation packaging bags for all aspects of daily life.

General Hot Selling Products

There will be many choices of twisted paper handle making machine for our customers. The following hot-selling products come from our customers’ long-term purchase data and our knowledge of products in the industry.

Water Glue Twisted Paper Handle Making Machine

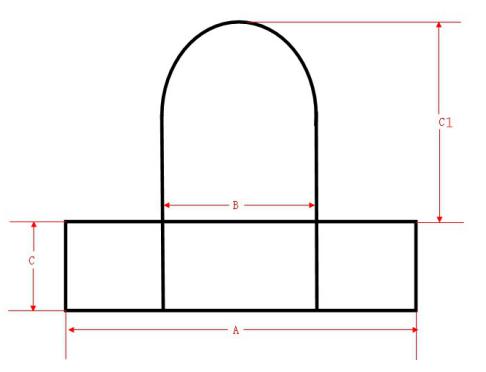

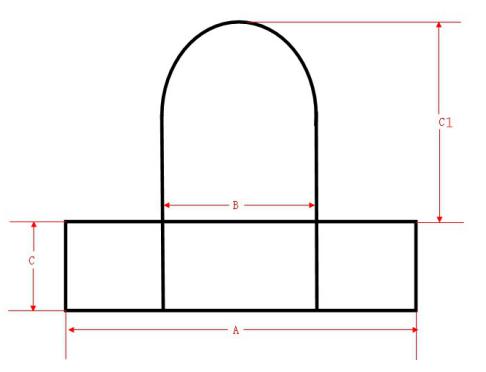

- Paper Sheet Length(A): 152-190mm(Optional)

- Paper Rop Handle Spacing(B): 75-95mm(Optional)

- Paper Sheet Width(C): 40mm

- Paper Rope Height(C1): 100mm

- Paper Rope Diameter: 3.0-4.0mm

- Glue Type: Water Glue

- Production Speed: 10000pairs/hour

The machine adopts cold quick-drying glue to reduce raw material costs (hot melt adhesive is twice as the cold water glue), that widely used in the professional production of the paper bag. The machine is easy to operate and can produce paper handles with high speed usually reaching 150 pairs per minute. We design and offer the optional assembly line, which can automatic gluing replace the human gluing procedure so that help to reduce lots of labor costs. And it can increase the production speed and finish large quantities order. Cold glue won’t change and still stick firmly at low temperatures, which can ensure the quality of the handle.

Flat Paper Handle Making Machine

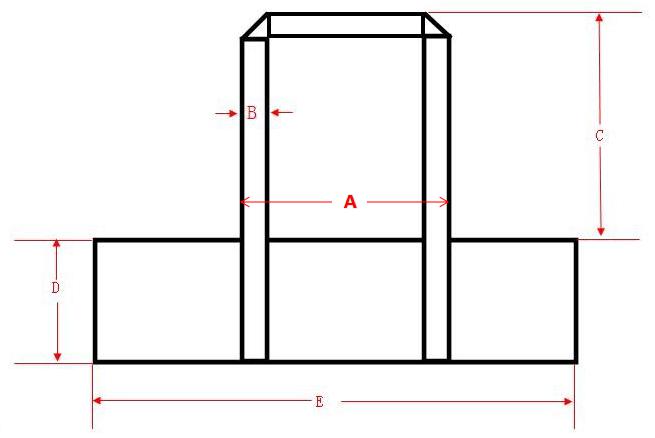

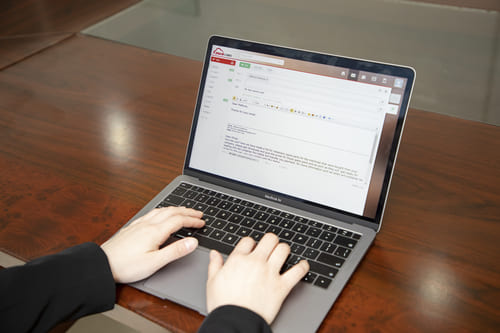

- Paper Rop Handle Spacing(A): 108mm

- Paper Rope Width(B): 12mm/15mm

- Paper Rope Height(C): 10mm

- Paper Sheet Width(D): 40mm

- Paper Sheet Length(E): 152/190mm(Optional)

- Paper Rope Length: 352mm

- Paper Gram Weight: 100-120g/㎡

- Production Speed: 6000pairs/hour

This machine is a high-speed machine for producing flat paper handles. which can be attached to the paper bag without handles, and make it into paper handbags. This machine takes four narrow paper rolls as raw material, through the complex production process to form right-angle flat paper handles. In addition, the machine also has automatic counting and gluing functions, which can greatly improve the efficiency of subsequent processing operations of users.

It is an ideal supporting machine for paper handbag making machine.

Hot Melt Glue Twisted Paper Handle Making Machine

- Paper Sheet Length(A): 152-190mm(Optional)

- Paper Rop Handle Spacing(B): 75-95mm(Optional)

- Paper Sheet Width(C): 40mm

- Paper Rope Height(C1): 100mm

- Paper Rope Diameter: 3.0-4.0mm

- Glue Type: Hot-melt Glue

- Paper Gram Weight: 100-130g/㎡

- Production Speed: 10000pairs/hour

This machine is a high-speed machine for producing twisted paper handles. which can be attached to the paper bag without handles, and make it into paper handbags. This machine takes two narrow paper rolls and one paper rope as raw material, sticks them together for forming paper handles. In addition, the machine also has automatic counting and gluing functions, which can greatly improve the efficiency of subsequent processing operations of users.

It is an ideal supporting machine for paper handbag making machine.

Automatic Twisted/Round Rope Paper Handle Making & Pasting Machine

- Paper Rop Handle Spacing(B): 75/95mm

- Paper Sheet Width(C): 40mm

- Paper Rope Length: 360mm

- Paper Rope Height: 140mm

- Paper Gram Weight: 80-140g/㎡

- Paper Bag Width: 250-400mm

- Paper Bag Height: 250-400mm

- Production Speed: 33-43pcs/min

- Gluing Type: Hot-melt Glue

This machine is mainly supporting semi-automatic paper bag machines. It can produce the round rope handle online, and stick the handle on the bag online too, which will make the paper bag without handles into paper handbags. This machine takes two narrow paper rolls and one paper rope as raw material, sticks them together for forming paper handles. In addition, the machine also has automatic counting, gluing, and pasting functions, which can greatly improve the efficiency of production.

Wanna more information on our products?

Estimated Cost Analysis For Twisted Paper Handle Making Machine

If you want to enter the paper bag production or paper bag machine sales industry, but do not know how much the budget should be, it will help you.Please note that the final cost depends on the customized service you require, the configuration of the machine used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

The final cost depends on the customized service you require, Such as the machine’s model,the configuration of the machine and the way of packing

$25,000

Take the philipinne as a example, due to the impact of COVID-19, the current price is rough $1,800/40HQ. This part of cost will be affected by the distance, policy and market.It is fluctuant, you can consult us or the freight forwarder.

$1,800

Estimated Insurance, customs duties, customs clearance charges at destination, inland freight charges at destination, bank charges for payment and other charges that may be incurred

No reference valueThe Process Flow & Duration Estimation

With the increasing number of customers approaching us, we have no other option but to prioritize speed and our service. Let’s look at the whole process of machine manufacture. Take an example of the standard machine.

20days-30days for standard twisted paper handle making machine

Step 1: Place Production Order ( 1-7 days)

Order confirmed and advance payment is received, we will place production order to production department according to the order priority. Our warehouse prepare materials and components as needed for manufacturing.

Step 2: Machine Manufacturing & Testing ( 10-20 days)

Skilled workers will begin processing materials, assembling components, connecting wires and testing the performance of the whole machine to ensure it works properly.

Step 3: Machine Inspecting & Packaging (1-3 days)

QC checks the appearance of the equipment and the list of accessories, the technician runs machine for a period of time on-site to ensure the machine can delivery. Final packaging as customer’ required after getting aproval.

Step 4: Booking & The Balance Payment Done (1-2 days)

Documentation staff will book the space according to the customer’s requirements. Meanwhile,the balance payment should be done on time.

Step 5: Shipping (10-15 days)

Arrangement of shipment, customs clearance, voyage period will depend on the distance of the route.

Want to know how to compress lead times?

We can calculate the exact delivery time for you depending on the machine model and the your specific requirements.

The Basic Knowledge About Paper Handle Machine

If you’re starting paper bag manufacturing or paper bag machine sales business, here’s the basic information you need to know

- Working Principle: Taking two narrow paper rolls and one paper rope as raw material, sticks them together for forming paper handles. In addition, the machine also has automatic counting and gluing functions.

- Suitable Paper Bags: Kraft paper bag without handles.

- Scope of application: Shopping Paper handbag, Takeaway food packaged bag, Gift packaged bag, Transport Bags, etc.

- Machine Speed: 30-500pcs/min, it will be different according to different machine model

- Gluing Type: Coldwater glue or Hot-melt glue

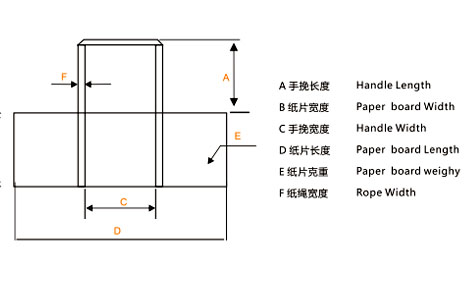

6. Twisted Paper handle size: Some size you should be know

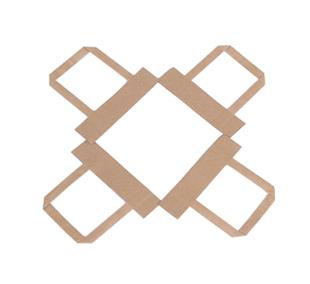

7. Twisted Paper Handle: This paper handle can be produced by our standard machine, also be called round paper handle.

8. Flat Paper handle size: Some sizes you should know when you want to make it.

9. Flat Paper Handle: This paper handle can be produced by our standard machine.

More information can be provided once we get your inquiry

The Common Categories When Purchasing

Twisted paper handle making machine is an ideal supporting machine for making eco-friendly paper handbags. Used in a wide range of industries, especially for shopping bags and takeout food packaged bags. It can be classified according to with handles or not as following.

- Water Glue Twisted Paper Handle Making Machine

- Flat Paper Handle Making Machine

- Hot melt Glue Twisted Paper Handle Making Machine

- Automatic Flat Paper Handle Making & Pasting Machine

- Twisted & Flat Paper Handle Making Machine

- Automatic Twisted Paper Handle Making & Pasting Machine

This machine is mainly supporting semi-automatic paper bag machines. It can quickly produce a twisted paper handle with twisted rope, which can be attached to the paper bag without handles in further production and make it into paper handbags. It is an ideal supporting machine for paper handbag making machine.

A Brief Self-Nomination, Why Choose XIAMEN COLORWIN?

Specialized in providing complete solutions for manufacturing all kinds of paper bag based on customers’ demand including all equipments, technology and after-sales service needs.

With more than 10 years’ experience and the solid relationship with all our manufacturers,we have already built business relationships with many countries and regions global customers. We focus on quality and service.

- Full range of machine types

- Machine’s speed is up to 200 pcs/min

- 1-Year Warranty for whole machine & Lifelong Service

- 24/7days,360℃ after-sale service

Our principle is to provide the most suitable products with reasonable price, the best service and worry free after-sales service for our customers.Win win is our final goal.

The FAQs About Paper Handle Making Machine

To save your time, we have listed and answered some questions that came from our new customers often. You can have a quick understanding of the twisted paper handle making machine

What is it ?

This machine is a high-speed machine for producing twisted/flat paper handles. which can be attached to the paper bag without handles, and make it into paper handbags. This machine takes two narrow paper rolls and one paper rope as raw material, sticks them together for forming paper handles. In addition, the machine also has automatic counting and gluing functions, which can greatly improve the efficiency of subsequent processing operations of users.

It is an ideal supporting machine for paper handbag making machine.

How to choose it ?

According to the type of bag, size of the bag, and your customized requirement.

You can also show us the sample of bag you want to product,We will give you recommendation.

Where it is mainly used?

It is especially suitable for the food and clothing industries. Used as shopping handbags, takeaway food packaged bags, etc.

What is it suitable for?

Squared bottom paper bag without handles.

What size paper bag can be made by it ?

Different machine models will have a different size range of the finished bags. Generally, the paper bag width is 250-400mm, paper bag length is also 250-400mm for our standard automatic twisted paper handle making and pasting machine.

What is the capacity of it?

Machine Speed: 30-500pcs/min, it will be different according to different machine models and produce different size paper handle.

Whether customization is acceptable?

Yes. we can develop & manufacture the machine as your customized requirement.

What is the power required for it ?

Usually, the power supply is 380V 3phase 4lines. However,it can be customized as your requirement.

Who can give me more help?

Get in touch with us, we will have a sales service for you specially.

1. Log in to the official website: www.itsmachinery.com

2. Call us directly: 0086 592-5996943/008618060975403

3. Welcome to the company: Unit 1012 Building A, No.3 Riyuanerli Huli District, Xiamen City, Fujian province, China

How to operate it ?

The machine is fully automatic and intelligent, with no need for manual gluing by staff. Only need 1-2 person monitor the production process or change materials. And technicians do some daily maintenance according to manual

How to delivery it?

By sea from Ningbo port or Shenzhen port. Usually, the whole machine is disassembled into several parts to make sure to load easily. The customer can assemble it according to the manual after receiving it.